Cable glands are often treated as small components, but their failure can cause major industrial accidents, downtime, and safety risks. From water ingress and cable pull-out to loss of explosion protection, a failed cable gland compromises the entire electrical system.

In this blog, we explain what really happens when a cable gland fails, the most common industrial failure scenarios, and how correct cable gland sizing, compression cable gland selection, certified ATEX cable glands, Ex cable glands, and proper cable gland accessories help prevent such failures.

This guide is especially useful for electrical engineers, EPC contractors, plant managers, and safety officers working in industrial and hazardous areas.

Why Cable Gland Failure Is a Serious Industrial Risk?

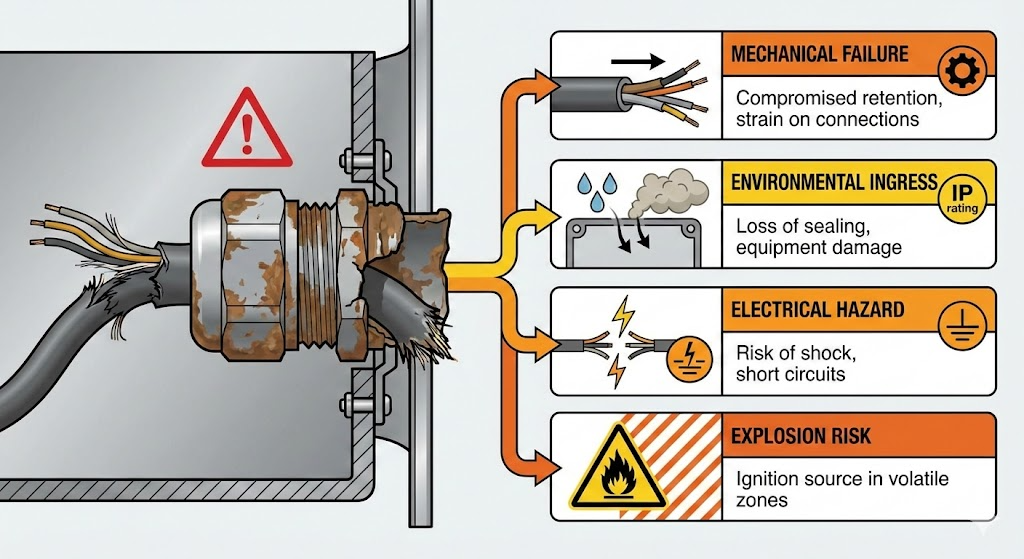

The image below shows how a failed cable gland can trigger multiple industrial risks, including mechanical failure, environmental ingress, electrical hazards, and explosion risk in hazardous zones.

Common Industrial Cable Gland Failure Scenarios

Cable gland failures rarely happen suddenly. In most industrial sites, they begin as small installation or selection mistakes that grow into serious operational and safety problems over time. Below are the most common real-world failure scenarios engineers encounter in the field.

1. Failure Due to Incorrect Cable Gland Sizing

Incorrect cable gland sizing is the most frequent and overlooked cause of gland failure in industrial installations.

What actually happens on site:

The gland does not grip the cable firmly

Sealing rings fail to compress properly

Continuous vibration allows cable movement

The enclosure gradually loses its IP rating

Real-world consequences:

Moisture and dust enter control panels

Cable insulation deteriorates faster

Short circuits and unexpected shutdowns occur

2. Compression Failure in Single or Double Compression Cable Glands

A compression cable gland depends on precise tightening to provide both sealing and mechanical retention. Too much or too little compression leads to failure.

Common installation mistakes:

Over-tightening damages sealing rings

Under-tightening allows cable pull-out

Using the wrong gland type for the cable construction

Correct selection matters:

| Cable Type | Correct Gland Type | Risk If Wrong Gland Is Used |

|---|---|---|

| Unarmoured | Single compression | Poor sealing or cable movement |

| Armoured | Double compression | Loss of earthing and weak grip |

3. Failure Due to Missing or Incorrect Cable Gland Accessories

In many inspections, the gland itself is fine the problem lies with missing or incorrect cable gland accessories.

Typical accessory-related failures:

No sealing washer → water ingress

Wrong locknut → gland loosens over time

Missing earth tag → ineffective grounding

Essential accessories for safe installation:

Sealing washers

Locknuts

Earth tags

Reducers and adapters

4. Failure of ATEX Cable Glands in Hazardous Areas

ATEX cable glands are specifically designed to prevent flame propagation and gas entry in explosive atmospheres. Failure here is critical.

Common causes of failure:

Non-certified gland installed in ATEX zones

Incorrect cable outer diameter selection

Improper tightening torque during installation

What’s at risk:

Loss of explosion containment

ATEX certification becomes invalid

Serious safety, legal, and compliance issues

5. Ex Cable Gland Failure Due to Improper Installation

Even certified Ex cable glands cannot protect equipment if they are installed incorrectly.

Typical installation errors:

Incorrect cable stripping length

Improper armour clamping

Wrong positioning of sealing components

Resulting risks:

Flame path integrity compromised

Gas ingress becomes possible

Equipment is no longer explosion-safe

Industries Where Cable Gland Failure Is Most Critical

Oil & Gas plants

Chemical & petrochemical industries

Power generation & substations

Pharmaceutical manufacturing

- Offshore and marine installations

Conclusion & Call-to-Action

Cable gland failure is not a minor issue it directly affects safety, compliance, and system reliability. Most failures are caused by incorrect cable gland sizing, wrong compression cable gland selection, missing cable gland accessories, or misuse of ATEX cable glands and Ex cable glands.

By using a proper cable and gland size chart, selecting the correct gland type, and following best installation practices, industrial failures can be completely avoided.

📩 Talk to our technical team today at Exgrip.com

📞 Or call us directly for quick assistance!

Contact Us:

📞 Phone: +91 9537118899

🌐 Website: www.exgrip.com

📩 Request a Quote: Contact Page

FAQs

What is the most common cause of cable gland failure?

Incorrect cable gland sizing is the most common cause, leading to poor sealing and mechanical instability.

Can wrong cable gland accessories cause failure?

Yes. Missing sealing washers, locknuts, or earth tags can cause leakage, loosening, and safety issues.

Why are ATEX cable glands important in hazardous areas?

ATEX cable glands prevent flame propagation and gas entry, ensuring explosion protection compliance.

Is a double compression cable gland better than single compression?

For armoured cables and outdoor or hazardous applications, double compression cable glands offer better sealing and mechanical strength.

How do I choose the correct gland size?

Always refer to a cable and gland size chart based on the actual cable outer diameter (OD).