In modern industrial electrical systems, cable glands are critical components that ensure safety, reliability, and long-term performance. These essential devices secure cables entering electrical equipment and protect them against environmental and mechanical stress.

A cable gland acts as a sealing and termination device, preventing dust, moisture, and other contaminants from entering electrical enclosures. It also provides strain relief, ensuring that the cable remains securely fixed, even in demanding industrial environments.

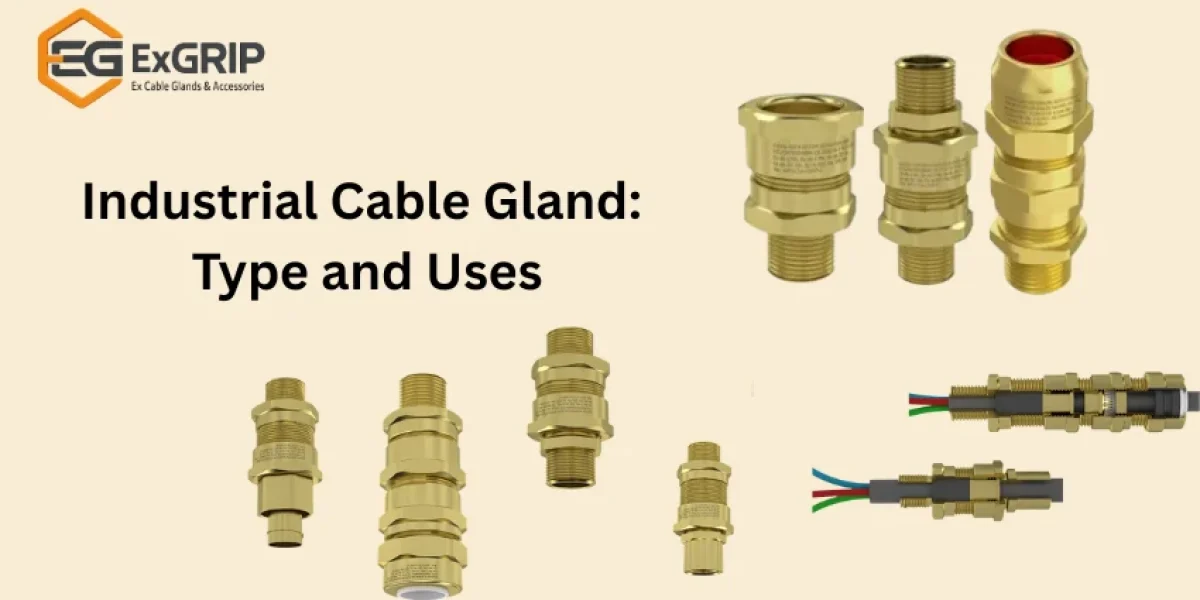

From armoured cable glands for heavy-duty installations to flameproof cable glands designed for hazardous areas, selecting the right type of gland is vital for operational safety and compliance with industrial standards.

At Exgrip, we specialize in providing high-quality industrial cable glands and accessories. This guide will help you understand different types of cable glands, their uses, and why selecting the correct product is essential for your project.

What is an Industrial Cable Gland?

An industrial cable gland is a mechanical connector that attaches and secures the end of a cable to equipment or enclosures. It provides mechanical protection while maintaining a safe and reliable connection.

Functions of Cable Glands:

- Sealing and Protection: Prevents ingress of dust, water, and other environmental elements.

- Mechanical Safety: Protects against twisting, pulling, and vibration.

- Electrical Continuity: For armoured cables, it maintains grounding and bonding between the cable and the equipment.

- Compliance with Standards: Meets safety regulations for industrial and hazardous locations.

These glands are typically made from brass, stainless steel, or high-grade plastics, depending on the application. Brass cable glands are particularly popular for their durability and corrosion resistance.

To ensure proper installation, engineers often refer to a cable gland size chart to match the gland precisely to the cable diameter.

Why Choosing the Right Cable Gland Matters

Using the wrong industrial cable gland can cause a variety of problems, such as:

- Loose connections leading to short circuits or system failures.

- Water or dust ingress damaging sensitive equipment.

- Non-compliance with safety standards, creating legal and operational risks.

- Increased maintenance costs due to frequent repairs or replacements.

For instance, in outdoor installations or hazardous environments, a flameproof cable gland or double compression cable gland is essential to prevent accidents and ensure reliable performance.

Choosing the right cable termination solution reduces downtime, enhances safety, and increases the lifespan of your electrical infrastructure.

Types of Industrial Cable Glands

Different environments require specific cable gland designs to handle unique operational challenges. Here are the most common types used in industries worldwide:

1. Single Compression Cable Glands

Best For: Unarmoured cables in indoor, controlled environments.

Features:

- Provides basic sealing and strain relief.

- Designed for locations where heavy mechanical protection isn’t necessary.

- Easy to install and cost-effective.

Applications:

- Control panels in factories.

- Junction boxes in commercial buildings.

- Internal wiring for machinery and equipment.

Single compression cable glands are commonly used in standard electrical installations where the risk of environmental exposure is minimal.

2. Double Compression Cable Glands

Best For: Armoured cables in outdoor or hazardous industrial locations.

Features:

- Provides sealing at both the inner sheath and outer sheath.

- Offers superior grip and prevents cable pull-out.

- Excellent resistance to dust, water, and mechanical stress.

Applications:

- Heavy-duty machinery and industrial motors.

- Outdoor installations exposed to rain and dust.

- Power distribution networks in factories and plants.

Double compression cable glands are ideal for industries like oil & gas, manufacturing, and energy because they deliver enhanced durability and sealing.

3. Armoured Cable Glands

Best For: Cables with metallic armour that require grounding and extra protection.

Features:

- Provides electrical continuity between the armour and equipment.

- Prevents accidental cable displacement during installation or operation.

- Protects cables from severe mechanical impacts.

Applications:

- Industrial plants and factories.

- Outdoor power transmission lines.

- Oil & gas facilities requiring high safety standards.

These glands are available in both single compression and double compression designs depending on your operational needs. Armoured cable glands are essential when grounding and mechanical stability are critical.

4. Flameproof Cable Glands (A2F Type)

Best For: Hazardous areas with explosive gases, vapors, or combustible dust.

Features:

- Contains internal explosions, preventing flames from reaching external areas.

Certified to ATEX, IECEx, and other international flameproof standards.

- Provides robust sealing and mechanical security.

Applications:

- Oil refineries and petrochemical plants.

- Chemical processing industries.

- Hazardous manufacturing zones.

Flameproof cable glands are crucial for industries where worker safety and regulatory compliance are top priorities.

5. Waterproof Cable Glands

Best For: Outdoor and wet environments where cables are exposed to moisture.

Features:

- Rated IP67 or IP68 for superior water resistance.

- Protects electrical systems during washdowns and in rainy conditions.

- Durable and long-lasting under extreme weather exposure.

Applications:

- Solar panel installations.

- Outdoor lighting and power systems.

- Marine and offshore industries.

Waterproof cable glands are perfect for ensuring reliable electrical performance in wet or humid environments.

How to Select the Right Industrial Cable Gland

Choosing the right gland is vital to achieving safe and efficient operations. Here’s what to consider before purchasing:

Cable Type: Determine if your cable is armoured or unarmoured.

Environment: Assess exposure to water, dust, chemicals, or explosive gases.

Material Selection:

Brass cable gland for general industrial use.

Stainless steel cable gland for corrosive environments.

Plastic cable gland for cost-effective indoor applications.

IP Rating: Match the environmental sealing level required, such as IP67 or IP68.

Compliance Standards: Check certifications like ATEX, IECEx, or UL for hazardous locations.

At Exgrip, we provide detailed cable gland size charts and technical assistance to help you choose the correct gland for every application.

Benefits of Using High-Quality Electrical Cable Glands

Investing in premium electrical cable glands offers several advantages:

Safety: Prevents electrical hazards and equipment failures.

Durability: Resists harsh environmental and mechanical conditions.

Cost Savings: Reduces maintenance expenses and downtime.

Compliance: Meets international safety and quality standards.

Performance: Ensures stable, secure, and efficient cable terminations.

By choosing trusted products like Exgrip cable termination solutions, you protect your infrastructure and workers while extending the life of your electrical systems.

How to Order Cable Glands from Us

Contact Us:

ou found this blog helpful, check some of the other blogs below:

- Need Cable Glands? Buy Explosion Proof Cable Glands Now

- Affordable and Trusted Cable Gland Types by Exgrip

For more insights and updates on web design for small businesses, follow us on Instagram, Facebook, LinkedIn, and Youtube.